Achieving precise and reliable bolt tightening is essential in the fast-paced industrial environment of today to guarantee the dependability and safety of buildings and machinery. Traditional manual bolting techniques can provide uneven torque applications, resulting in equipment failures and safety risks. Electric hydraulic torque wrench pumps have become a dependable and effective way to address these issues. The Electric Hydraulic Torque Wrench Pump delivers reliable power for precise torque applications in a compact, efficient design.

Hydraulic Torque Wrench System

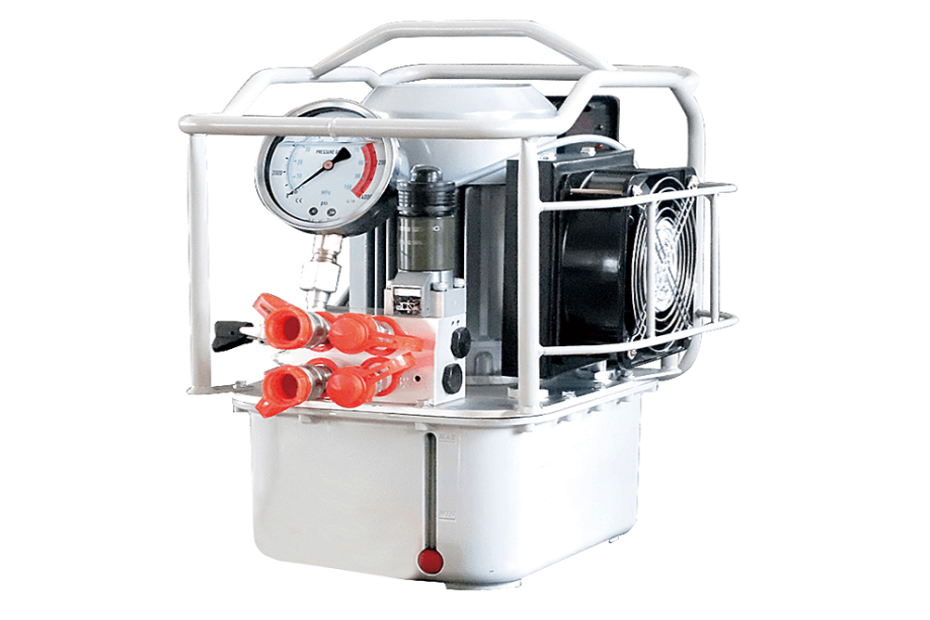

A small, transportable device called the electric hydraulic torque wrench pump is used to power hydraulic torque wrenches in commercial bolting operations. A hydraulic pump with an electric motor is responsible for providing the torque wrench with controlled hydraulic pressure. The torque wrench is then rotated as the high-pressure hydraulic fluid is utilized to torque the nuts and bolts precisely.

Consistent and Efficient Electric Pumps

The electric motor that powers the pump has several advantages over conventional pneumatic or manual approaches. Electric pumps operate more consistently and efficiently since they don’t require manual work or compressed air. The electric motor can also maintain optimal operating temperatures with a high-performance radiator, ensuring reliable and efficient performance.

Monitoring Torque Pressure

The torque wrench is powered by high-pressure hydraulic fluid produced by the hydraulic pump, which utilizes High-efficiency three-stage flow pressure design. It guarantees a consistent flow of hydraulic pressure, enabling precise and consistent torque applications. Users can set and maintain specified torque values using the pressure control system built into the torque wrench pump. This feature ensures controlled tightening and prevents over-torquing, reducing the risk of damage to components. Many modern electric hydraulic torque wrench pumps feature a user-friendly digital display that allows operators to monitor pressure, torque values, and other essential parameters.

Motorized Hydraulic Torque Wrench

The motorized hydraulic torque wrench pump provides unparalleled bolt-tightening precision. It enables users to continuously attain precise torque levels, guaranteeing uniform bolt tension across all fasteners. Electric hydraulic pumps significantly shorten the time needed for applying torque compared to hand bolting. During the bolting process, automated operations and rapid setup save crucial time. The pressure control system and digital pump monitoring decrease the risk of damaging bolts, nuts, or equipment, which prevents over-torquing.

Ensuring Product Integrity

The pump tightens big bolts in steel buildings, bridges, and heavy equipment in building projects. The assembly of components in industrial processes, where accurate and consistent torque is necessary for product integrity, depends on the pump. The pump ensures that wellheads, pipelines, and other essential parts are assembled correctly in the oil and gas sector. Turbines, generators, and other power-producing machinery are maintained and serviced using electric hydraulic pumps.

Enhancing Industrial Bolting Efficiency

In industrial bolting, the electronic, hydraulic torque wrench pump is revolutionary. This technology has advanced to the point that it is a necessary tool for many different industries. It offers exact torque application, time savings, increased safety, and portability. As technology develops, we may anticipate more improvements in electric hydraulic pumps, bolting process optimization, and overall industrial efficiency.